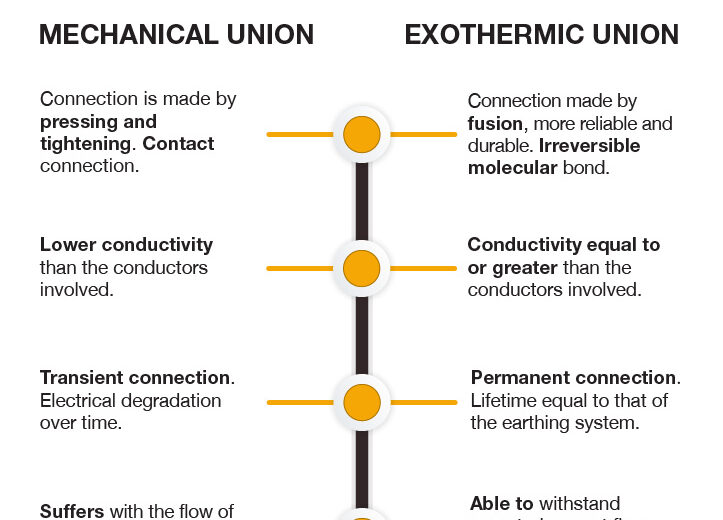

Exothermic welding and mechanical unions can have a similar application at a glance; however, their results and benefits differ greatly.

An exothermic welded joint has a connection made by fusion, which is more reliable and durable. The result is an irreversible molecular bond. The conductivity of the union itself is equal to or greater than the conductors involved. As a consequence, the connection is permanent with a lifetime equal to that of the earthing system.

Exothermic welding does not require high maintenance, as it is able to withstand repeated current flow without degrading. Once the mould is closed, the exothermic welding process is autonomous, reproducible and uniform.

On the other hand, in a mechanical union, the connection is made by pressing and tightening, resulting in a contact connection. The joint has a lower conductivity than the conductors involved and the connection is transient, since it presents electrical degradation over time.

Mechanical unions suffer with the flow of current, faults or repetitive discharges and the result of the connection depends on the tightening torque applied by the installer.