A new international regulation, IEC 63052:2019, was published Last August 2019. It regulates the quality, safety and electromagnetic compatibility requirements for protectors against permanent or temporary overvoltages, also known by their acronym POP (Power Overvoltage Protectors).

This publication extends the existent European standard EN 50550:2011, modifying some points such as the classification of the protectors, but maintaining the operating principles and the tripping curve.

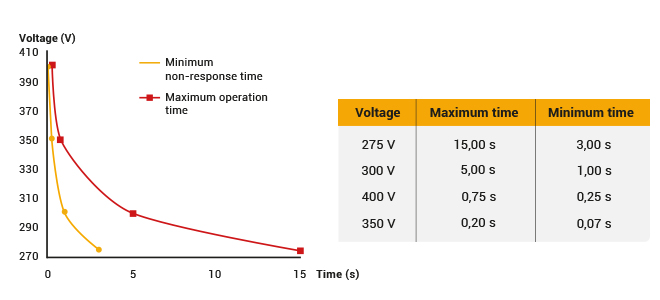

Tripping curve:

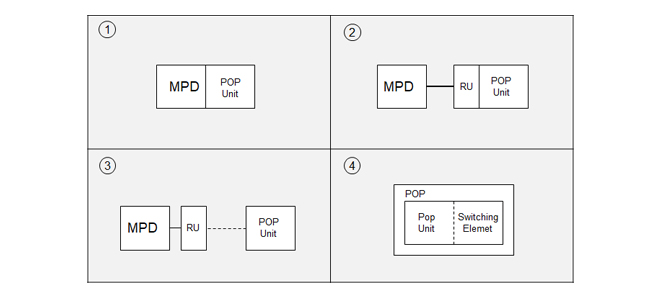

The new standard now distinguishes 4 types of protectors, depending on how they are constructed:

1. POP unit assembled to the main protective device by the manufacturer as one device. For example, IGA TEST type protectors.

2. POP unit with a release unit (RU) mechanically coupled on site with a main protective device (MPD).

3. POP unit to be electrically coupled on site with the release unit (RU) attached to the main protective device (MPD). For example, ATCONTROL KIT type protectors.

4. Protector (POP) that includes an internal switching element. For example, the ATCONTROL COMPACT type protectors.

Classification of protectors:

The permanent or temporary overvoltages are increases in voltage above 10% of the nominal value of the distribution network which remain for several cycles or even permanently. They are usually caused by a defective connection of the neutral or a failure in the transformation center.

The permanent or temporary overvoltage protectors are devices that help to keep facilities and equipment safe by disconnecting the power supply in time by means of a cut-off device.

If the times marked in the tripping curve are not met, certain problems may occur in the facilities such as:

- Shots out of time: the protector cuts the supply before the minimum time with no response, thus annoying normal operation.

- Late shots: the cut-off occurs above the maximum operating time, which may cause irreparable damage to equipment.

Aplicaciones Tecnológicas S.A manufactures self-configuring protectors that manage the triggering of the cutting element in a microcontrolled way, correctly adapting the times depending on the detected voltage in order to comply with the standards. Our products are tested in independent laboratories with the specifications of the relevant standards and offer all the guarantees of a leading company.

This functionality of self-configuration is a characteristic of our ATCONTROL series protectors. This allows us to universalize them, using the same equipment in any international market.

If you need more information or have any doubt about our products do not hesitate to contact our technical support department using this link.